RetroArms

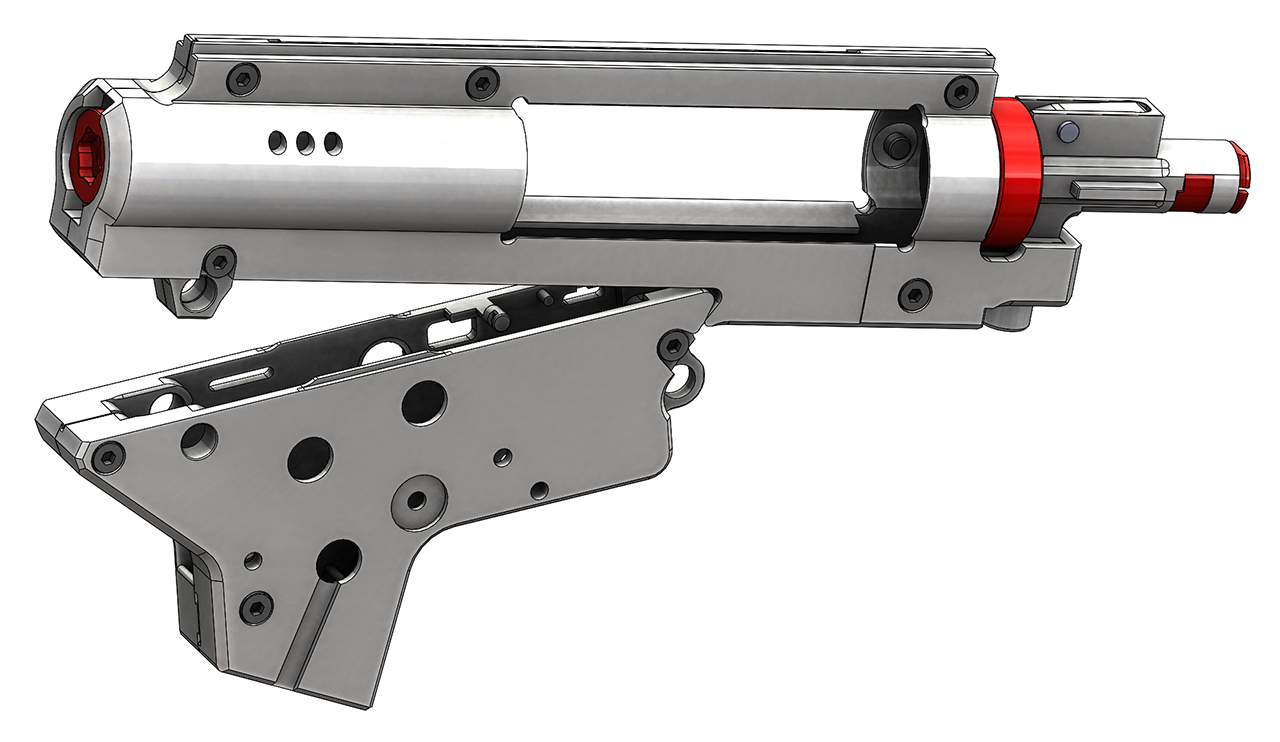

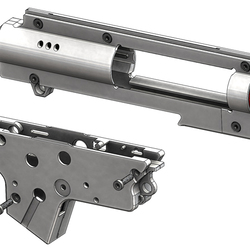

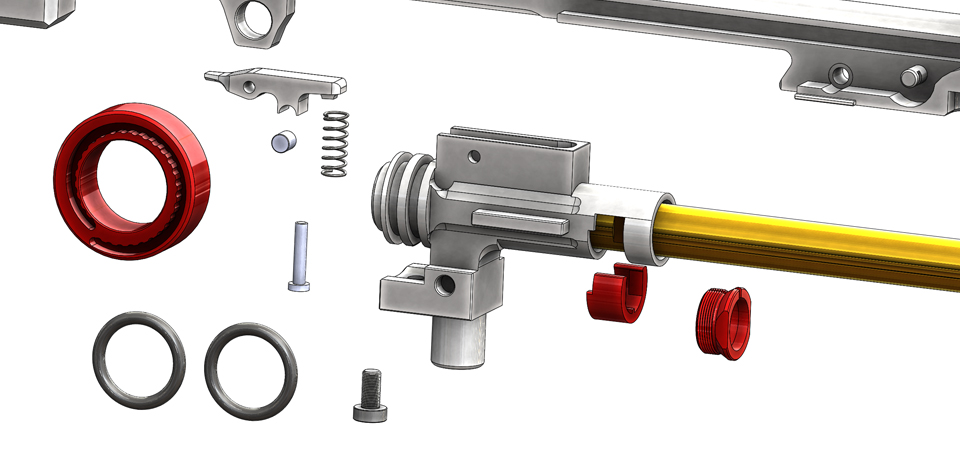

This is brand new CNC gearbox ver. II with integrated Hop Up chamber and ball bearing spring guide for 8mm bushings

This is brand new CNC gearbox ver. II with integrated Hop Up chamber. It is manufactured from aircraft dural EN AW 7075, what have strength of steel and weight of aluminum, it is best for high performance builds. Gearbox is milled on CNC milling machine and has protective anodizing of 5µm silver color (0,005 mm).

This gearbox is lengthwise divided on three parts: Lower part, Upper Part and Hop Up chamber. Best advantage of this gearbox is integrated Hop Up chamber. Because of that, the chamber don’t jump-off and it is part of gearbox. The chamber is installed together with upper gearbox part, so the chamber is fixed and always in straight line with inner barrel. This prevents from problems with falsely casted weapon’s bodies, what does not have straight line (missfeeding, Hop-Up chambers out of line, less performance). This divided gearbox construction making installation into the weapon’s body very easy and fast.

Upper part of gearbox was more reinforced.

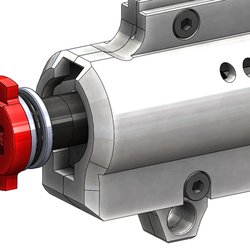

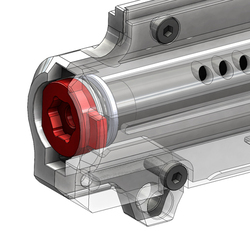

For best connection of inner barrel and Hop Up chamber, we used special collet nut, what is placed in front of the Hop Up chamber. Simply put inner barrel with bucking into the Hop Up chamber, seal it with C-clip lock and in the end screw the collet nut it with 10 mm key into the chamber. Collet nut is manufactured from aircraft dural EN AW 7075 and after easy screwing of the nut, it will hold inner barrel very tight. Do not use rude force to screw collet nut, otherwise you will damage it and inner barrel would overturn. Sign of right tightening is less space of gap on the collet nut.

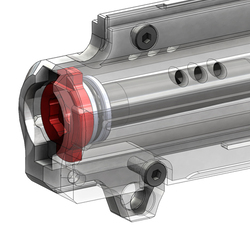

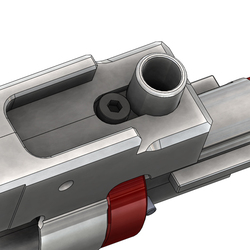

Our Hop Up chamber has new adjusting pressure system. Basic plastic gear was replaced for metal one (aircraft dural EN AW 7075). This regulation gear has serrated surface for better regulation without slipping. Inner groove is made with notches, so when you regulate Hop-Up, chosen regulation will not change, even when you use high performance springs. On regulation gear pressures 0,5 kg spring, what prevents from performance deflections while shooting from airsoft replica. Our pushing lever is made for using common Hop Up spacers. Package does not include spacers! You have to use your own, or you can buy spare Hop Up spacers from teflon and silicon.

Best performance was achieved with our new generation Hop Up bucking and nozzle with length of 21,3 mm, more of testing here.

This gearbox is Tokyo Marui compatible. You can use parts from any manufacturer with TM standard.

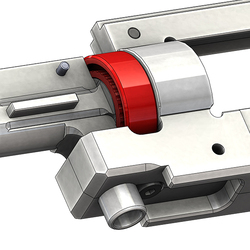

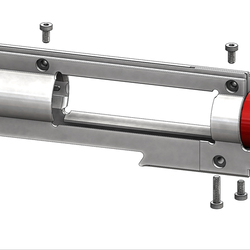

This gearbox has quick spring change system - QSC. You can change your spring without needing of disassemble whole gearbox. Installation of gearbox upper part is also very easy, you can put spring with spring guider in the end, when you have gearbox assembled in weapon’s body. For spring change, you will need 8 mm hex key. The spring guider was also reinforced for prevention of breaking with high performance springs.

Spring guide’s conic part is milled on CNC lathe from 90MnCrV8 material, what is basically tool steel that is hardened in vacuum on 55HRC hardness. Basic body of spring guider is manufactured on CNC milling machine from aircraft dural EN AW 7075 and both of these parts are connected with M6x1 thread and glued together with Loctite thread glue. Spring guider is pushed only by force of the spring, so you have to secure it, on M4 replicas is that by screwing the stock bolt.

Upper and lower part of gearbox is completely milled on CNC milling machine, there no added elements like on the past generation gearboxes. For connecting together of both parts of gearbox are used tightness bolts 10.8 with hex head for 2,5mm key.

Lower part changelog:

Milled grooves for springs, anti-revers, trigger and trigger blocker are not falling out now.

Removed pins for connecting of upper and lower part of gearbox, replaced with milled locks.

More space for wiring under the motor.

Reworked space for trigger switch, cut-off lever and connector plug.

New housings for bearings/bushings drilled by special 7,98 mm drill. Bearings will not fall out now, cutted edges for easy installation.

Reworked fire selector plate catch.

Different angle for pistol grip and lowered lower part of gearbox for better installation to all bodies.

Lower part is also reinforced for non-problematic use of spiral gears.